Physical properties and measurements of the wood

Density ρ=M/V

We have used two methods to measure the density ρ=M/V

Volume displacement

For this method we need a big plastic barrel with an adapted tap in the upper part, and another bucket to recover the displaced water.

We fill the barrel and let the water overflow till the last drop comes out.

Weight the dry wood wedge.

Insert the wood wedge and maintain it carefully sunken with the help of a thin metal stick and let it remain sunken until the last drop has come out.

Weigh the displaced water and the wet wood wedge.

The volume of the wedge will be the sum of the displaced water plus the difference between the weights of the wedge (We have to consider the absorbed water by the wood)

Geometric method

Plane the wedge til it fits perfecly with the geometric figure. Planes must be as regular as possible.

Weigh the wedge.

Measure it in different places to obtain a mean value and use the formula to calculate the volume.

The formula will give us the density ρ=M/V with the mass or weight of the wedge.

Environmental conditions

Be aware of the weather conditions.

With relative air humidity variations the measurement of the density will be pretty different.

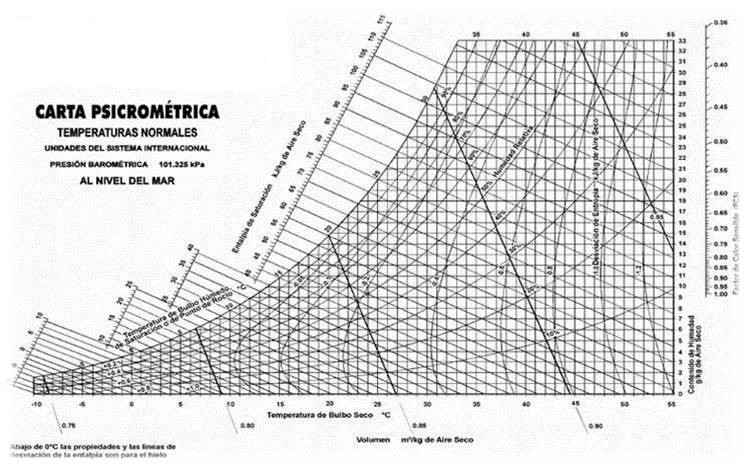

This relative air humidity can be calculated with a psichrometer (dry bulb temperature minus wet bulb temperature) and its corresponding psichrometric chart.

Some defined environmental temperature and humidity conditions can be fixed to calculate the density and make it comparable.

We know that the Equilibrium Moisture Content stabilizes in all woods under some specific enviromental conditions. This value could reach 18% in a wet week and descend to 5% in a dry one, crosing a usual value of 11%. We will have very different values of the density in the same piece of wood.

Wedge weight at 11% 375.2gr, with a volume of 0.972xE-3 m3

EMC weight density

18% 399 gr 410 kg/m3

11% 375 gr 386 kg/m3

5% 355 gr 365 kg/m3

A close cabinet with a controled moisture and temperature gives us 33ºC and 44% air humidity measured with the psichrometer.

This enviromental conditions can be obtained with UV-A and incandescent lamps.

The wood reaches an Equilibrium Moisture Content of 8%. We can consider this value as a standard value, as the wood has to be worked with a quite low value of moisture content.

Density on maple (kg/m3)

Reference Water displ. Geometric.

12317-A 558 561

12318-B 573 588

12319-C 565 580

12322-D 560 569

12571-E 572 576

12575-F 570 571

Density on spruce (kg/m3)

Reference Water displ. Geometric.

20/1-A 380 383,1

20/2-B 390 386,0

20/6-C 370 371,9

20/7-D 370 377,3

20/ 8-E 360 363,4

20/ 9-F 370 364,7

Sound velocity C on wood

We have used two methods to measure the sound velocity C on wood: the Lucchi Meter and the longitudinal waves method.

LucchiMeter

The Lucchi Meter measuring equipment is very sensitive to the place where you put the sensors.

The C value also changes with the force yapplied to the sensors.

We measured all the CNC machined plates with the sensors at the same point and with the same force, driven by the weight of a 2,9 kg piece of iron, positioned above the top receiver sensor

Longitudinal waves

We know that the frequencies of the longitudinal waves in an air column have an harmonic relation, as well as in wood columns (the length almost ten times the diameter of the column)

We plane one wedge to have the same section over the length L(it’s not exacly a column…)

We hit one side with a hammer and measure with a microphone on the other side the stationary waves. The FFT software gives us the frequency f of the first longitudinal mode.

We calculate C=2*L*f

It is not an easy task to find similar.

The search of a suitable set of wood was complicated because they had to be similar between them on their physical characteristics and these had to fit in the ones required for this project (apart of being aesthetically alike to the Huberman)

C 0n maple (m/s)

Reference Long. wav. LuchiM wedge LuchiM back routed

12317-A 4468 4801 4447

12318-B 4623 5130 4474

12319-C 4431 4784 4373

12322-D 4391 4826 4363

12571-E 4355 4702 4272

12575-F 4511 5000 4534

C 0n spruce (m/s)

Reference Long. wav. LuchiM wedge LuchiM top routed

20/1-A 5326 5514 4622

20/2-B 5508 5786 4803

20/6-C 5598 5797 4448

20/7-D 5530 5788 4916

20/ 8-E 5468 5656 4856

20/ 9-F 5490 5660 4876

We can observe the inferior value of C measured in the CNC tops, in which the wave travels the arching crossing the grain with certain angle.

This doesn’t happen in the wedge in which the wave travels parallel to the grain. The C value decreases in the spruce with the crossing angle.